can u show me what fan you are using and how u mounted a fan for your a/c condensor…i had thought of half radiator but im keeping my ac and haven’t seen one before lol

All my ac stuff is out of the car right now. BUT, how I had planned on doing it is like this. I was gonna run a slim fan on the half size rad and on the condenser. Pretty straight forward. Right now i’m using the stock cooling fan on the radiator. I took all my ac out because one the condenser was blown, but two because my friend wanted his turbo back which means im gonna get a bigger one…might not be able to keep my ac. Hoped that helped…i’m tired man

Haven’t posted anything in awhile cause I just haven’t gotten anything else, buuuut I’ve got a boost and oil pressure gauge on the way =] I haven’t seen them yet, but I think they’re both glowshift. My friend ordered them for me for working on his evo. I should have my turbo and oil return as well once I’m done building this evo so fingers crossed that car turns out alright that way mine can too lol

Got my boost gauge and oil pressure gauge in the mail yesterday so today I decided to figure out where they needed to be mounted. I figured since the car doesn’t have ac anymore…who needs vents? So I made another carbon fiber piece. Unfortunatly the boost gauge does not appear to be working correctly =[ It reads 22 psi when the car is off, and 11 psi at idle. My friend bought these for me off some guy so kinda sucks that it’s not working right. I don’t know if the oil pressure gauge works or not cause I’m not gonna put that on until the sandwich plate goes on for the turbo. Anyway, here are some photos of it

^That’s real carbon fiber btw, not wrap. Cut it all out from an old hood

Love how it looks behind the AC knobs, you should cut some more and sell them. haha.

Thanks. I wish I could, but I don’t have enough carbon fiber left to do that. The last piece I have is so messed up I doubt it’s repairable.

Installed my oil pressure gauge today with help from Jose =]

(Other hole is for the boost gauge)

Got another piece for it today, thanks to Jose. That other one I got from alfredo was just too shitty. This one is 100 times better and the wastegate is actually centered over all 4 runners instead of just 2.

Nice

Thanks.

Friend gave me this as part of my payment for doing some work for him =] It’s a legit one too, not knock off

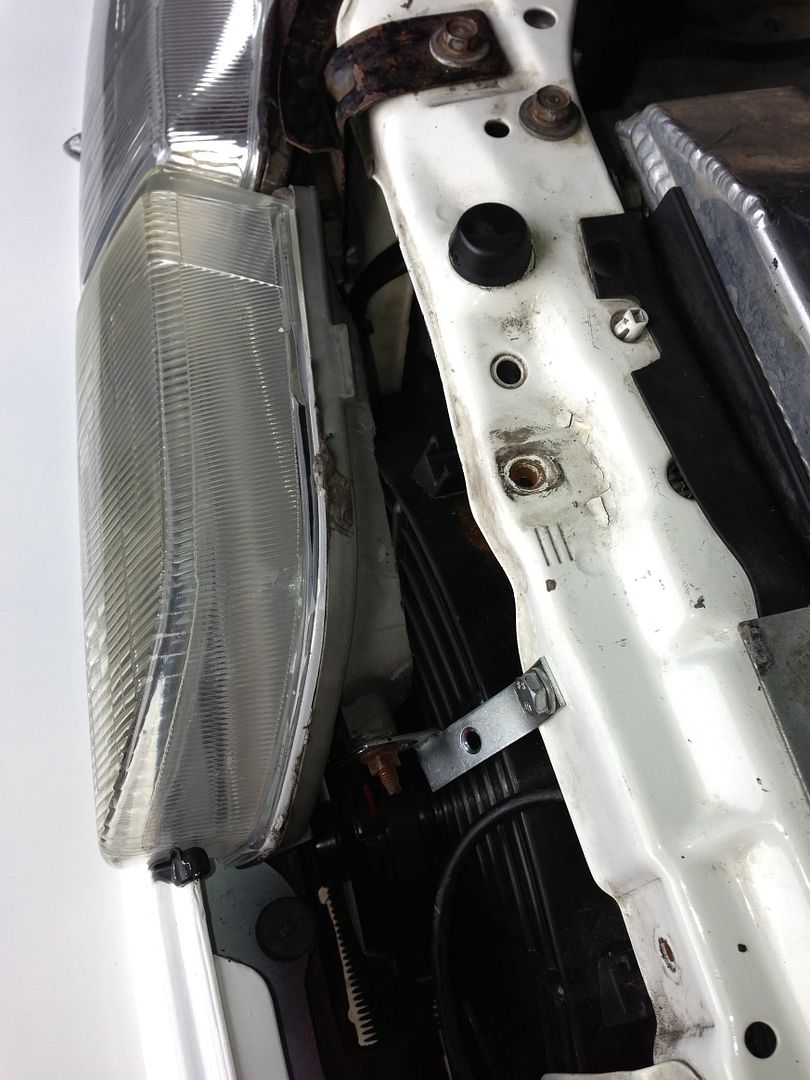

Not sure if you got an answer yet… I used two slim FAL fans mounted in front of the condensor and wired them as pusher fans. The only thing fitment wise was I had to notch the back side of the bumper support to clear the electric motors. I also had to get rid of the fog lights to get them to clear. I need to cut off the backs of the fogs and figure a way to mount them to hold them in place.

^Nice, sucks about the fog lights though.

Does anyone understand how to plot compressor maps? These things are kicking my ass lol I hate math. I’ve plotted a few, but I don’t think I’m doing it correctly. I just wanna make sure I’m doing this right so I can pick the correct turbo for my set up

[QUOTE=512_SIR II;2299209]^Nice, sucks about the fog lights though.

Does anyone understand how to plot compressor maps? These things are kicking my ass lol I hate math. I’ve plotted a few, but I don’t think I’m doing it correctly. I just wanna make sure I’m doing this right so I can pick the correct turbo for my set up[/QUOTE]

Are you on honda-tech? if so search user/sponsor SHodan. He sourced me the gt32b. Garrett, ball bearing, qwick spool, won’t sacrifice top end. They make 450ish hp max, I have full boost around 4800-5000 rpm, 13lbs. made 400whp on my stock b17.

[QUOTE=512_SIR II;2299209]^Nice, sucks about the fog lights though.

[/QUOTE]

I figured out a way mount the lenses, but unfortunately, the fogs are non-functioning. There just wasn’t enough space in behind to keep the guts of the fogs.

Cool, I’ll see if I can get a hold of him. I’ve been doing a lot of compressor map research, but still haven’t made any final choices. I was looking at Precisions turbos until I emailed them asking for compressor maps and they said “We don’t release those. We go off real dyno data”. I replied “Oh…well that’s not helpful for a consumer who is trying to make a decision on which product to buy. I’ll go with Garrett then.” So i’ll get a garret I just don’t know which one. It wont be the gt series. I can’t afford a turbo over $1000

Looks good. I would of just mounted it on the other side of the condenser

[QUOTE=512_SIR II;2300507]Cool, I’ll see if I can get a hold of him. I’ve been doing a lot of compressor map research, but still haven’t made any final choices. I was looking at Precisions turbos until I emailed them asking for compressor maps and they said “We don’t release those. We go off real dyno data”. I replied “Oh…well that’s not helpful for a consumer who is trying to make a decision on which product to buy. I’ll go with Garrett then.” So i’ll get a garret I just don’t know which one. It wont be the gt series. I can’t afford a turbo over $100

Looks good. I would of just mounted it on the other side of the condenser[/QUOTE]

My turbo was close to 900$ but worth every penny!

Shodan also pointed out if you need parts for a precision turbo down the road you can only use their parts specific. Garretts have alot more support base.

All saabs, volvos used garretts and never had turbo issues for easily 100k miles.

My last ebay turbo lasted 5 years but prolly only 10k miles and wasn’t close to pushing it’s limits.

[QUOTE=Sirtef9;2300519]My turbo was close to 900$ but worth every penny!

Shodan also pointed out if you need parts for a precision turbo down the road you can only use their parts specific. Garretts have alot more support base.

All saabs, volvos used garretts and never had turbo issues for easily 100k miles.

My last ebay turbo lasted 5 years but prolly only 10k miles and wasn’t close to pushing it’s limits.[/QUOTE]

Shodan never responded to me… =[ lol Oh well. I’ve got a friend who is a dealer for Borg Warner and said he can get me a deal on those. He was telling me to look at the s256 which I did and the compressor map looks favorable for my set up, but not as much so as the garrets I had been looking at. I’ve heard a lot of good things about bw turbos though and apparently they’re built like tanks. I just wanna pick something soon cause I’m starting to get antsy and I wanna get this set up moving. I feel like it’s been idle for too long now.

I’ll post up more info or photos as things happen. I still want to try and have this mostly done by the end of the year, but i’m not holding my breath. My new goal is to really just have it 100% done by tx2k14 which in next march. Should have no problem reaching that goal =]

So I finally picked out the turbo I’m going with =] I’ll be ordering it at the end of the week and will post photos once it’s here in my hands =]! I’ll let it be a surprise

Ok so looking for some advise on catch can set ups. I’ve been told by some people that I wont need one with the psi and power goals i’m aiming for (11-13 psi 250-300 hp), and others tell me it’s a must have thing no matter what. So i’m a bit confused =\

If I do need to run a catch can set up these are some ideas I had in mind.

Method # 1

- Leave the stock black box and pcv valve in place as is. Get one of those big ports for the back of the block to run to the catch can as well, and run the stock port on the valve cover to the catch can along with it.

Method # 2

- Leave the stock black box in place, but eliminate the pcv valve and run the hose off the top of the black box to the catch can, and run the stock port on the valve cover to the catch can along with it.

Method # 3

- Remove the stock pvc system all together, run 2 ports from the back of the block to the catch can, and run the stock port on the valve cover to the catch can along with it as well

I don’t know if any of those are good ideas, or if they’re even necessary with my psi and power goals. btw if you’re reading this and don’t know my set up i’m on a stock b16a.

Any info or advise on this would be great, thanks

Have you looked at the PVC setup options from the Turbo guide? I originally had the one with the open vent off of the top of the valve cover but I found it was always releasing fumes directly into the air vents for the HVAC system so the interior always smelled of fumes. I ended up changing it to the closed system per the guide and it doesn’t seem to smell as much and the car seems to run quieter too (I could be imagining this part though)…

Method 2 appears the most restrictive. Every engine breathes a little bit different, but the ultimate goal is to remove as much bypass gasses as possible. I had my B16 turboed with the same power goals as yours and ran your method 2. The engine eventually failed, but I’m not sure it was attributed to the poor breathing capabilities. Most people say you don’t need a catch can below 300HP, but I would suggest one. Method1 seems counter productive cause the black box IS taking up one of your 2 ports for the block to vent, pluss if the PCV should fail, it Will provide positive pressure to the engine. Method 3 is your best option, and you could also add on those breathable valve covers with the dual vent ports(this might increase your total cost though). Good luck, it’s a win-win cause you’re considering the options. Just don’t keep it stock.

Yea I have, but those crude drawings confuse the hell out of me for some reason lol. I don’t have a/c anymore so shouldn’t be too much of an issue (wish I still did though)

After reviewing a bunch of set ups online in my same power goal, and talking with a good friend of mine (who has been boosting cars for longer than I’ve been alive) I decided to go with #1. Yes, the pcv valve could fail, but I’ll still have one other port on the block that is fail proof as well as the one on the valve cover so the engine would still be able to breathe. I’ve never had a pcv fail on me either, but I’ll put a new oem one in as a just in case. Everyone I talked with said #3 just caused way too much oil loss, and I don’t really wanna deal with that. If it turns out the method I’ve chosen isn’t sufficient then I’ll do what needs to be done in order to correct it.

Anyway, here is the catch can. It was chrome which would of looked stupid in my engine bay so I painted it black, got some basic fittings for it, and it’s ready to go.

I also got a fitting for the back of the block from honda (part #11107-pk2-003) and the washer for it as well (part #12207-634-300) I didn’t take a picture of these but here is one I found online

Now I just need to get some hose for it and bolt it up (already test fitted it and made a bracket to mount it back near the firewall next to the fuel filter)

I’m still waiting on my turbo as well =[ I was really hoping that would come in this week, but I don’t know what’s taking it so long. I’ll post more photos once this is installed as well as when the turbo comes in