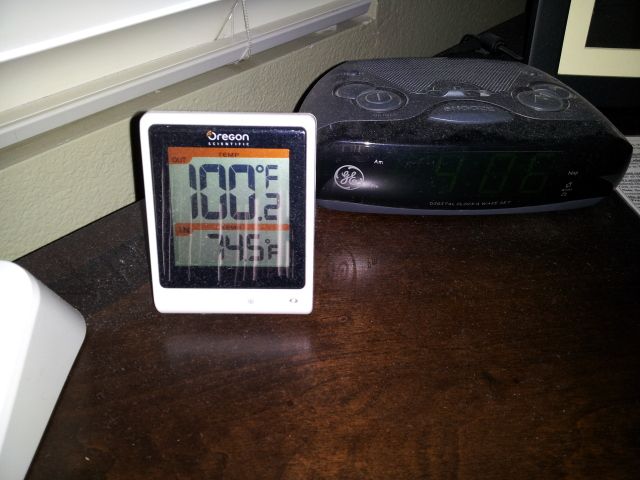

Well as much as I would like to get rid of my ac components for that clean engine bay look, reality is that I live in a part of Southern Cali that gets too dam hot in the summer. July-August we easily see 100+ degrees almost every day. Here is a pic of just the other day in late June:

My DA9 is my daily driver and when I get in my car on those hot days I see/feel this:

Almost 120 degrees inside the DA!

I’ve owned my DA since 2009 and I finally got tired of driving with my windows down at 80mph on my way to work.

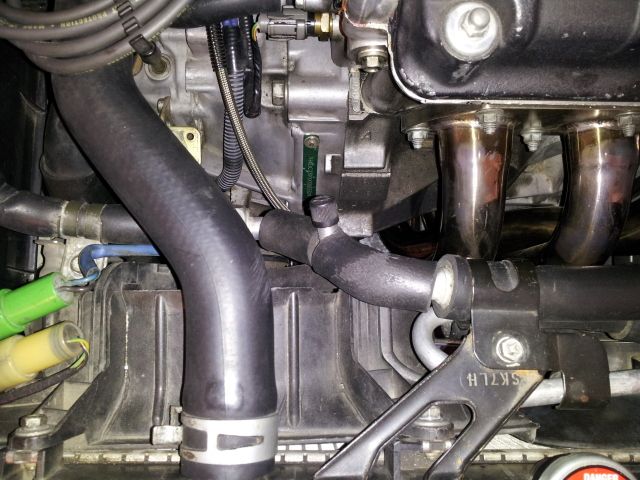

I knew I was leaking freon, because I had seen it, from the high-side service port:

And you can also see it was leaking from the top connection on the condenser (dry oil stain)

I decided to do a R134 conversion since R12 is no longer an option and R134 is readily available at most auto shops.

After doing my homework, I also decided to change all my orings (engine bay only) and the dryer. The oem orings and dryer are almost 23 yrs old and I highly recommend changing them.

I found the o-ring kit on ebay for $9 shipped. Part# MT2561

I also found the drier on ebay for $20 shipped. 4 seasons Part# 33279

You will need to convert the stock service ports to R134. They sell the adapter kits at most auto part stores.

The short one is the high-side and the long one goes on the low-side.

Buy the kit that includes the schraeder valves that go inside the port. It comes with the tool to remove and install them. You may as well change them since they are 20+ years old and are known to leak.

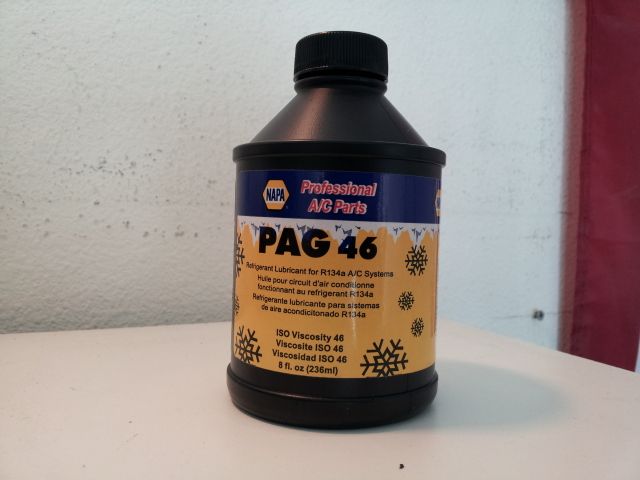

The AC compressor uses 5 ounces of PAG 46 oil.

I bought this 8 ounce bottle at NAPA for $9. I added the oil through the low-side inlet on the compressor.

In order to change all the orings in the engine bay, you need to remove the front bumper. There is a connection on the bottom of the condenser and there are two more line connections that have orings. I left the bumper off until I was done adding freon just in case I had a leak and needed to make a repair.

I also changed the oring under the cap on the compressor that is held by 4 allen screws. There are at least 10 orings that I changed. Anywhere there is a nut or bolt holding or connecting a line, an oring needs replaced. The only place I did not change orings was under the dash where the evaporator is. I pretty sure that the metering valve has an oring but I was not in the mood to remove my dash, not unless I knew there was a leak there.

The drier is held down by 2 10mm bolts. Having the front bumper off makes this job easier. You will find an oring on each line connected to the drier. You will need a 19mm and 17mm wrench. Or you can use two adjustable wrenches to undo any nuts on the lines.

I used an ac manifold ($55) I picked up at harbor freight tools and a vacuum pump ($16). The pump needs to be hooked up to an air compressor. There is a pump that doesn’t use a compressor but it costs around $100. I hooked everything up and opened up both high and low side valves in order to pull a vacuum.

You can see the vacuum pump hooked up to the yellow line. After 15 minutes I turned off the valves and checked to see if the system held vacuum. If it doesn’t, it means you have a leak. Mine held and I opened up the valves and ran it for another 15 minutes.

Next it was time for the freon. I shut the valves on the manifold and removed the pump. I hooked up my first bottle of R134. I found the 12 oz. bottle at Wal-Mart for $12. California requires a stupid $10 deposit. So you actually pay $22 for one can and you get your $10 back when you return the empty can. You have 90 days to get your money back…stupid Cali smog rules.

The instructions in the helms manual require you to purge the yellow line prior to pushing freon through the manifold. Then with the car OFF you open up the high side and add about 10 oz of freon. This prevents the compressor from running dry when you start the car. Next you close the high side and start the car. The helms call for 2500 rpm and the AC on on max air and max fan. Open up the low-side and start adding the rest of the freon until the proper psi is reached. PSI is different for everyone due to outside temp, so I’m not going to put a set number on it. Mine, for my outside temp, was around 45psi.

I monitored my vent temp with a thermometer. I started with an inside temp of 80 degrees. The best I was able to get it was 40 degrees! Weird was that I didn’t even use two full cans of R134! Most of my research says that you want to be in the 40 degree range coming out of your vents.

It was great driving to work with the windows up and the AC blasting! No more turning the volume up on my radio because of the wind noise. Now I just have to replace my blower resistor so I have more than just max and off on my fan settings ![]()