Cool . . . let us know when to send you payment. ![]()

dan put me down for the future list please.

:sipread:

if you have room for another person put me down for #3 as well. :rockon:

i’m very interested in option 3. paypal ready. ill keep following this thread. thanks

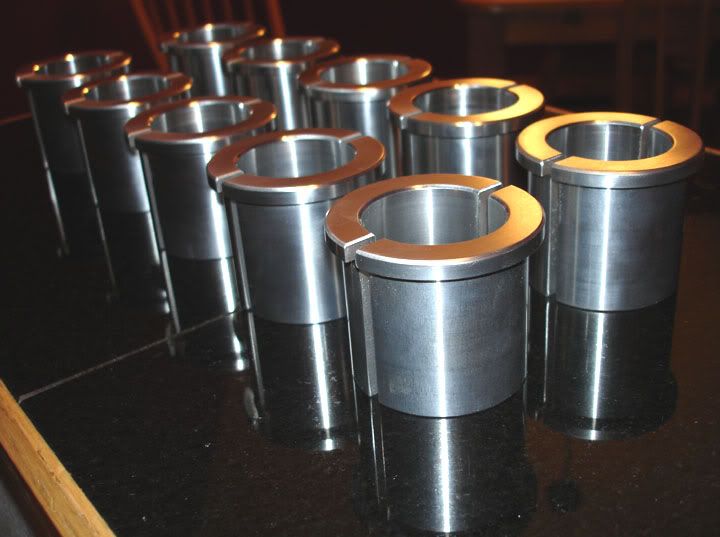

Good news!!! Bushings are done. They needed a bit of “finish” work as they didn’t meet my strict quality standards. Even though they are under the car, they should look nice ;). I finished them up today and will test fit them ASAP. If they fit properly they’ll be ready to ship.

WOW! Nice work Dan. Let us know how the test fit goes. ![]()

Sweet! I still would like in on some if you making more!

Okay, jacked my car up this morning to verify a couple of things. My custom shim is the perfect height so that’s good.

But we may have a couple of issues. The measurement I got from BLKACK1 of the DA bushing length (from left to right) was 43mm. I believe this number to be accurate. However, the ES Poly bushing may be a bit shorter (as I measured mine and it was 40mm. This is an issue because the bushing sits right against the edge of the tie rod boot. The other problem is that the custom bushing inner diameter is almost too tight. I saw almost as it actually sits flush against the rack. But you have to push it into place (almost like snapping it on). This may be bad for some as the racks may vary ±.01". This would leave some of you sanding some of the paint off the rack or using some sand paper to open up the inner diameter a bit. Basically this leaves us with two options:

-

Leave the bushings as they are and let each individual fit them for their application. Shouldn’t need a lot of modification. Grind 2mm off the unseen side of the bushing (the side without the flange). And the possible sanding of the ID of the bushing or the rack itself.

-

I can modify all of the bushings (machining them all 2mm shorter on the end mill) and I can open up the ID using the sanding method as well.

Does anyone else have a ES poly bushing they can measure the length of (left to right as if it were installed in the car) ?

[QUOTE=G2guru;2055937]Okay, jacked my car up this morning to verify a couple of things. My custom shim is the perfect height so that’s good.

But we may have a couple of issues. The measurement I got from BLKACK1 of the DA bushing length (from left to right) was 43mm. I believe this number to be accurate. However, the ES Poly bushing may be a bit shorter (as I measured mine and it was 40mm. This is an issue because the bushing sits right against the edge of the tie rod boot. So this leaves us with two options. The other problem is that the custom bushing inner diameter is almost too tight. I saw almost as it actually sits flush against the rack. But you have to push it into place (almost like snapping it on). This may be bad for some as the racks may vary ±.01". This would leave some of you sanding some of the paint off the rack or using some sand paper to open up the inner diameter a bit. Basically this leaves us with two options:

-

Leave the bushings as they are and let each individual fit them for their application. Shouldn’t need a lot of modification. Grind 2mm off the unseen side of the bushing (the side without the flange). And the possible sanding of the ID of the bushing or the rack itselt.

-

I can modify all of the bushings (machining them all 2mm shorter on the end mill) and I can open up the ID using the sanding method as well.

Does anyone else have a ES poly bushing they can measure the length of (left to right as if it were installed in the car) ?[/QUOTE]

i think you shoudl leave em alone. some of us might get lucky and they snap right in no prob, the otheres may have to machine. but ti’s better than the off chance we have to add something to make it fit right.

I agree with your statement about the ID of the bushings. However, with regards to the length, having them too long will now allow the flange of the aluminum bushing to sit flush against the rubber or poly bushing as there is only so much room between the tie rod boot and the rack bushing. Having the aluminum bushing a little short (by 2mm… we’re not talking a huge amount here) will just allow the rubber or poly bushing to over hang the aluminum bushing a bit. I would like everyone involved here to chime in as I’d like to get them modified today if necessary.

As far as the inner daimeter goes, I would say maybe it might be best to have them milled down from the get go, but as long as its just going to take a little sanding to get it to fit properly then it might not be a bad idea to let the individual buyer handle finnal fittment issues.

what ever decision you make, im confident it will be in all our best interests.

BTW those things looks solid, I applaude you effort on making this happen:clap:

[QUOTE=BLKACK1;2055973]As far as the inner daimeter goes, I would say maybe it might be best to have them milled down from the get go, but as long as its just going to take a little sanding to get it to fit properly then it might not be a bad idea to let the individual buyer handle finnal fittment issues.

what ever decision you make, im confident it will be in all our best interests.

BTW those things looks solid, I applaude you effort on making this happen:clap:[/QUOTE]

Yes, for the future I will open up the inner diameter by at least 1mm. So instead of 37mm I would open it up to 38mm. Since it’s two halves it will still contact the rack and do it’s job. Obviously I can’t put them back on the lathe now. But I can definitely shorten them up (lengthwise for you guys). I have the tools to do this easier than the average garage tools would allow.

That sounds like a good plan. If it’s not too much, I don’t mind doing a little sanding to make the inner diameter fit. But, you’re right about shortening it. I don’t have any tools that will be able to do the job . . . not a clean job atleast.

ah oh i follow you now. i misunderstood.

Wow they look awesome Dan! I have an ES rack bushing at home I can measure up for you when I get back from work. The ID should be easy enough to take care of individually but I agree the length may be an issue. I’ll get back to you asap.

I say mill them shorter, and we can take care of the ID sanding. And damn those things are looking quite bueno! :rockon:

Okay, I used Teflon between the bushings and the vice as to not damage the surface and it was going great until I tried to go too deep too fast. One half of the bushing came up and the end mill cut into the back side a little uneven :bang:. That means I only have 9 perfect sets now ![]() . The last set will work fine, it just has an odd “oblong” cosmetic blemish on the back side (the side you will never see even if the car is jacked up). The blemish is about 1/16" deep and 1/2" long. So I’m offering the last set at a $10 discount. If no one wants the last set with the small cosmetic blemish, I only have 9 to sell until I have more made.

. The last set will work fine, it just has an odd “oblong” cosmetic blemish on the back side (the side you will never see even if the car is jacked up). The blemish is about 1/16" deep and 1/2" long. So I’m offering the last set at a $10 discount. If no one wants the last set with the small cosmetic blemish, I only have 9 to sell until I have more made.

They look pretty awesome!! Aren’t you glad that I brought up this topic, Guru? You get to make a couple of bucks off of it. ![]() Let me know when you are ready for payment homie.

Let me know when you are ready for payment homie.

Great news. I was able to machine the rest of them down to 40mm without incident. Ready to start accepting payments if you guys still want them.