hi everyone just wanted to get a post up and ask for tips and advice as i go with my build

head…b18c1 gsr head

skunk2 intake manifold

70mm tb

stock gsr injectors

ebay header with a 2.5in collecter pretty nice actually

ebay 2.5in cat back

test pipe

diymike ls vtec kit

gsr head studs

skunk2 springs retainers and valve

block…b18a1block

arp rod bolts

acl bearings

gsr girdle and oil pump

thats about all i have as far as the block goes…my question is which cams should i run for a daily driven car that will see a road course on weekends. im looking into he pro2s for he strong mid range power and stock idle but the pro3s are only a little more so im trying to decide but any help or advice from u guys would be great…thank

im building something similar and i went with the tuner 2 cams

How did you like them…glad to see theres people doin da’s in texas imma be movin back there

still in the build process, had a wild hair go up my butt so the cars in for paint rite now lol

but ima be doing road courses and dailying as well

Lol ya i fell ya on that mine is definatly a rattle can special lol…ill post picks up soon for it…

Im tryi to see what kind of dynos i can find with the different cam types and how there power curves look

Nobody is runnin pro 2s or cams like it any info would help out alot

Pro2s are going to be a pretty big cam unless you go with really high compression… I mean, 12+:1

The non-vtec lobe will make power to about 7k-rpm… so unless you have high compression, and plan to rev your motor to 9,500+, it’s going to be too big for you.

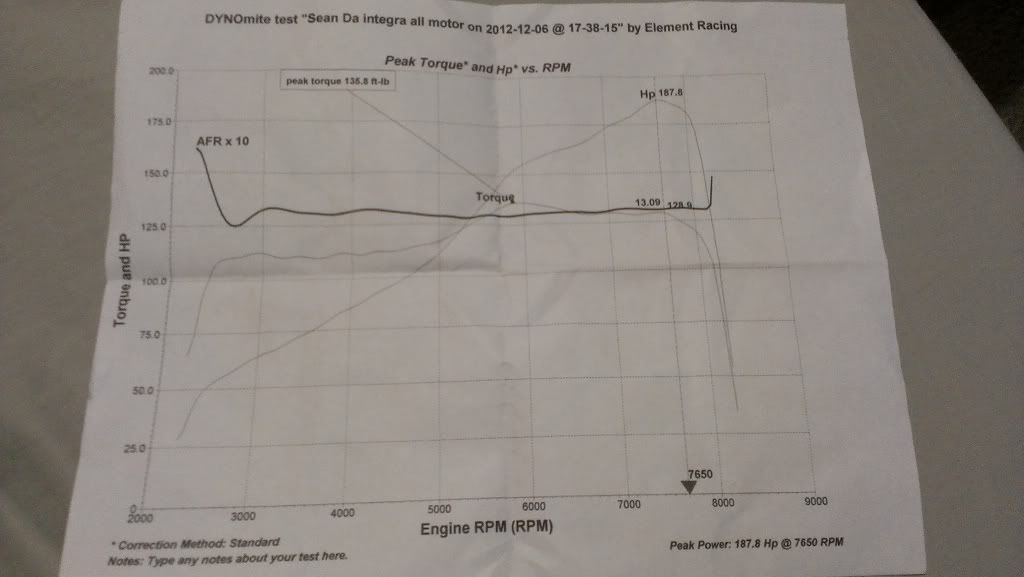

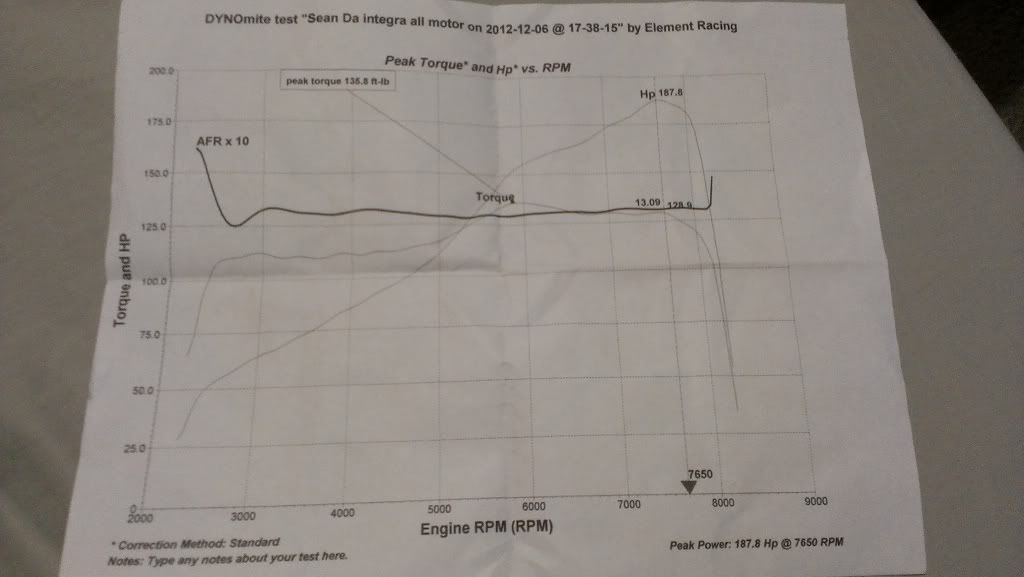

This is a high compression B16, port/polished head, flat faced valves, etc… Virtually as built as you can go while staying 81mm/1.6L, with just Pro1s and here is the graph:

Vtec engagement is VERY high in comparison to other cams (7,200rpm), and power dropped odd at 9k… You’d yield a better, more useable powerband if you went with something smaller.

The stock LS compression is NOT enough to make full use of those cams… you’d need pistons with a bigger dome.

I’d recommend you get ARP main bolts as well, to hold that bottom end together.

Why are you going with a GSR girdle? As long as you have ARP hardware, the LS block can do 9k reliably… Using GSR main-caps (which is necessary when running a gar girdle) can be bad news.

Stick with the original LS main caps, slap some ARP bolts in, and call it good.

You could even call Skunk2 and ask them, they’re great guys… I’d put money up that they recommend against anything bigger than a Tuner1 cam in a stock-compression lsvtec

My two cents worth.

yea im gonna be running the tuner2s but i also will be using cp 11.5 pistons…as for the gsr girdle i see why he used it, if honda put it in their vtec motor dont u think it should be there? i know i plan on using one as well…

also wanna clear something up on oil pumps…theres no such thing as a GSR, TYPE R, or LS oil pump…honda only has 2 part numbers for the oil pump and they are for obd1 and obd2…the oil pump is the same in LS, GSR, and TYPE R in all obd1 motors and then its the same in all obd2 motors

Obd2 pumps are all the same, that is true…

The girdle is not necessary. The B16 didn’t come with one, and it revs higher than any of the B18 motors…

I’m not saying its a bad thing, but more problems can arise from using main-caps from a different motor versus just beefing up the LS hardware and running it as is.

There are just as many people using girdles as there are people not running them. I’ve never seen a motor fail due to NOT using a girdle. For circuit racing they’re a good idea… For 1/4mile and street driving, they’re a bit overkill.

But if you got em, run em.

You can machine the stock LS main caps down to integrate the GSR girdle, but imo it’s more trouble than its worth. Been revving my LS to 8,600 with no girdle and it just asks for more.

you might want to try the tuner 2, they actually have.a more aggressive lift than pro 1. or so I’ve heard.

As I was saying in my posts above… BIGGER doesn’t mean better, it can hinder your performance. You want a cam that matches the rest of your setup.

Too big of a cam will hurt your low/mid powerband.

My best advice is to call the company who you plan to buy from, and ask which cam they recommend.

As an afterthought my brother and I called Skunk2, Endyn and a few other companies and they all said that the Pro1 we went with was WAY too big for the motor… they even went as far as saying the 70mm throttlebody was hurting his power gains.

You really want to match all of your parts so that they work together…

Being that the head and block of this setup is virtually stock, something along the lines of a ITR cam would yield the best performance.

Like I said, call around and get informed opinions from the companies themselves. they will steer you in the right direction.

Thank u guys for your info…so what im understanding is go with a type r cam set up correct…and i got my tb with my manifold as a deal so imma try it out and if it is infact hurting the power. Then imma just sell it for a 68mm…

Also i like the thought of not having to use the gsr girdle. Im not gunna be running it at 9k max is maybe 8k…but as my gsr head sits now it still has type r valves and valve springs in it, so i guess imma try and look around for some type r cams and just call it a day…any other thoughts on this build would be great all the info is amazing…one more question is say i went with a type r style piston maybe rs machine or another company so i could raise my comp ratio

ya i was gonna say the 70mm throttle body is too big…im waiting for the 68 to come back into stock…

Ya im startin to see that lol…but now im thinking of ordering a different set of pistons so i can raise the comp ratio up more…im thinking of going with the pro 2s for the time being since i found a good deal for them from a friend and a little later putting in the higher comp pistons

I’m running a 70mm throttlebody with a port-matched ITR manifold, R cams etc and made some good power…

If you already have the Type-R springs, I’d just run the R cams as well. That’s why I chose the cams I did, my head had the ITR springs and valves. So rather than fork out extra cash for new springs to go with new cams I said screw it and matched the two together.

Fresh off the dyno, my car only makes power to 7,800rpm… That’s only 1k above a stock LS redline… with ARP hardware, the extra 1k rpm does not call for the addition of a girdle imo.

RS Machine make great stuff… I personally am running JE pistons with a spec that is bigger than a JDM ITR piston, but not as big as a CTR piston, and I’m sitting around 11.4:1.

Compression isn’t EVERYTHING, it doesnt yield huge power, but the cylinder pressure is needed to run those big ass Pro2s.

Check out my build thread and the parts I used to get that power… you don’t have to go crazy to make good power.

Do NOT get bigger cams unless you match the springs…

The old “keep stock redline and you’ll be fine” attitude is BS… No matter what rpm you run, if the lift is bigger than the R cam, the springs are likely to bind because they aren’t meant to be compressed with that extra lift of a bigger cam.

So with just the addition of r cams and keeping the r springs and retainers and valves alomg with the 70mm and sk2 im i should still see good numbers…cause my over all goal is to hit 200whp on the motor which i kno is hard to do with a 1.8 but i really want to try and shoot for it…but i have seen some other builds with stock bottom ends makin 190-200whp…but they are using the arp hardware of course. So if i can save a few extra $ with the type r set up i like the idea of it…thank u for ur advice and i believe imma go with the type r set up…

Can u send the link so i can check out your build thread

I hit 187whp… with a little work I could probably see 190’something… 200whp would be a far reach imo…

Here’s my thread: http://forums.g2ic.com/showthread.php?203377-Long-build-in-process

The first post has the mods, and page 12 has the dyno graph and video.

Ya i was seein my goal of 200 is a lil hard to reach on pretty much a mild built head ya kno…maybe a 75 shot lol