so i was looking at my bay and decided to do a brake line tuck. i was looking at using steel braided hose to run behind the firewall to the prop valve ( i think its called ) for the lines in the bay. that way i dont have to have custom bent hard lines. i was wondering what fittings i should use with them and what type of shop ( if i need to ) should i have do the fittings and custom length steel braided hose?

This thread is awesome.

thanks man. i should be updating on the weekend. got a new spool of wire so ill be finishing welding in the bay in the next few days. will keep it updated. sorta figured out what i need for my brake line tuck.

Man how did your tranny blew? The same thing happen to me

the spider gears inside the diff blew apart… idk how.

heres my update; welded the holes on the front support. thats as far as i got this weekend. rest of the bay will come in time. not the best welds but they will do

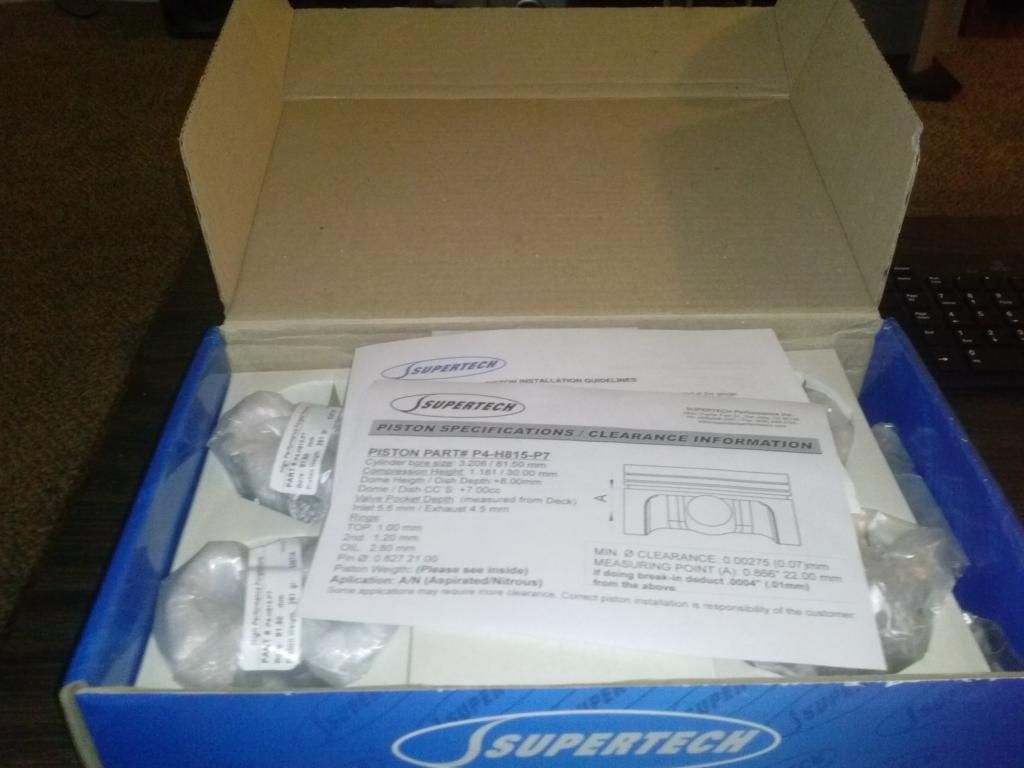

update for everyone. just finished welding/shaving the bay. now i have to go over with bondo for a smooth finish then itll be ready for paint. hopefully will be painted by middle of next week. also i was considering using cast pistons but decided to order a set of supertech forged pistons with a 12.4;1 compression ratio… which at my altitude brings me to aprox 11.4;1 effective compression ratio which should be real fun when i turbo in march.

reused this bracket that was on the firewall and welded it below my passenger head light for my radiator overflow can. what you guys think?

I like that idea.

Wow, that is so much work! Looking forward to seeing the result. For the brake lines, you will definitely want to use hard lines.

yea ended up deciding that i would use hard lines. just didnt wanna fuck up on the bends and flares. but should i should be ok with it.

also my pistons should be in monday. cant wait lol . i love getting parts in the mail. its like christmas everytime

this is all i got done today. welded a plate of sheet metal behind the holes on the firewall and bondo’d the front. came out nice

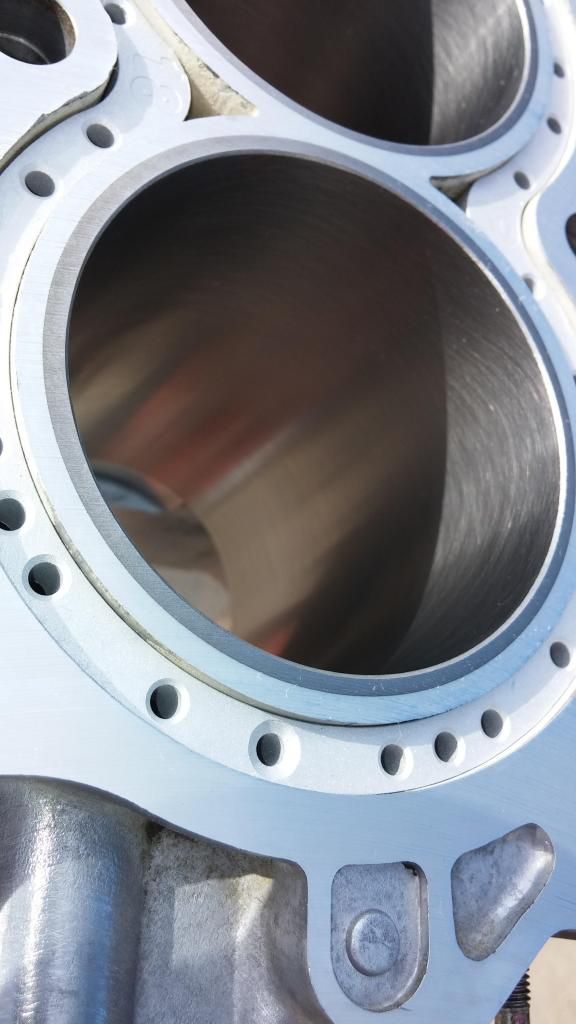

update : just got my pistons in today. also spoke to my tuner/machine shop and i will have the block guard installed, block decked and bored to 81.5mm, and head resurfaced done by hopefully friday. btw supertech pistons are made by mahle. so they are really good bang for your buck on a forged piston.

Just dropped off the block and head at the machine shop hopefully will get them back next week tuesday/wednesday time. Tommorrow i will do finishing touches on the bay and paint it saturday.

Just use a quality tool and it’s really not too difficult at all. Ridgid makes good tools for flaring, I love mine. Well worth the money.

You work fast! I’m looking forward to seeing this done!

well i was on leave the past two weeks. i have to go back to work on monday so eh. most likely will get paint done in the next 4 days. been lazy so havent done much to it haha.

talked to the machine shop today and found out i wont get the head and block back till probably thursday or friday… bummer.