for some reason i find this project really inspiring because i myself am going throught the whole “boost in the works” thing. you are an awsome example of what can be done with some good old brick headed-ness.![]()

![]() good luck on the long road to come!

good luck on the long road to come!

updates?

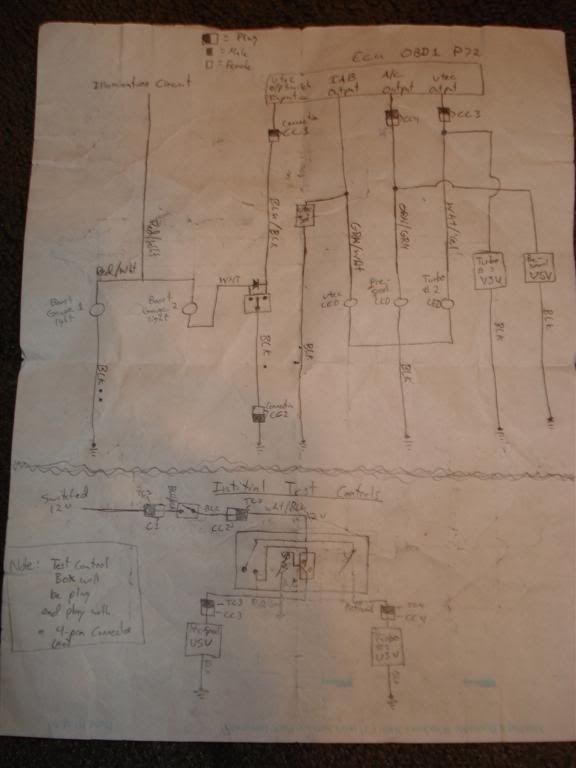

Nothing too exciting… got both carbon fiber autometer gauges installed in the center console: 1 vac/boost for the intake manifold pressure, 1 just boost for turbo2. Got those two, the switch and the LED’s wired up and tested. It’s kinda cool because I’ve been learning about automotive eletrical circuts at school for the past two weeks, so I was able to use what I learned to make the switch work the way i wanted without having to add a relay. Just used a diode (Which I previously had no idea what one did). Now UP will activate the turbo2 and illuminate the 2nd boost gauge, and DOWN will just illuminate the gauge without activating turbo2. I’m also waiting for my sources to do their jobs with my manifold pieces. Can’t rush people when they are doing favors.

And I decided to finally convert my car back to OBD1. It’s a 92 gsr that I bought at 16 as a theft recovery. All the wiring was cut up, so I swapped the body harness with my parts car, which was a 90 gs. At the time I had no idea what I was doing, but now I have access to another DB2 parts car so I’m going to make the switch. Anybody have a great deal on a P72 ecu and a good obd1 distributor? Must be a P72 ecu so I can use the IAB output for my new vtec trigger. Also, is the IAB output 12v? If not, I’ll use a relay.

this looks like a good project. I can’t wait to see the finished product!

i would group the cylinder pairs the same as a split scroll turbo. ![]()

I will almost guarantee its not 12v. its used as a signal out of the ecu, therefore the voltage will be very low, probably 4v.

you need to look at an ETM to determine what will be the proper voltage output to signal the VTEC solenoid, i forgot what that uses.

i would group the cylinder pairs the same as a split scroll turbo.

The way I’m doing the manifold (simple log style) is required if the sequential system is going to work properly. I would like to explore some more exotic manifold designs once everything is done and working properly. If i can make a better one that fits, I’ll make it out of stainless.

The vtec solenoid does use 12v, I’m sure of it.

Also, I’ve been looking at the Neptune RTP demo that I downloaded, and I realized it ALREADY has all of the necessary input/output functions that I need to make my sequential setup work. So now I’ll either have to make crome do all of those things, or bite the bullet and buy Neptune.

ignore this post, I changed my mind lol.

WOW!!! kyguy i can’t believe all of the comments you got. i havent read your thread in awhile; and it is great progress.![]() let me know when you need some help and i will try to be there!!

let me know when you need some help and i will try to be there!!

Not enough time in the day!!!

Here are some pics!

Finished center console. Notice the ~1ft hoses coming off the gauges to make the console removable without the need of loosening the fittings on the backs of the gauges. I’ll just pull the barbs out of the hoses.

close-up of gauges

Looks a lot more simple from the front!

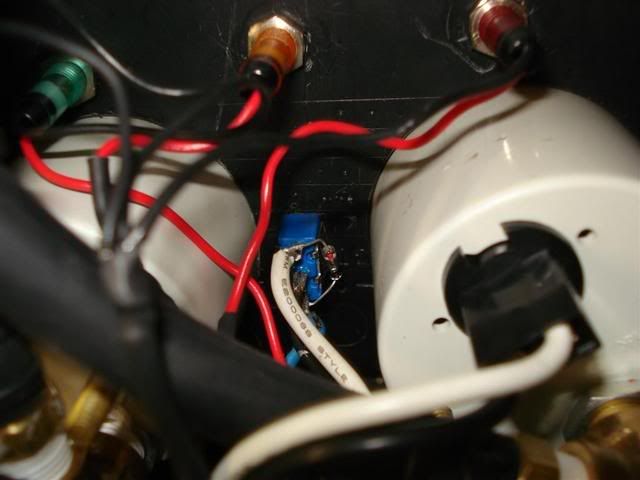

Close-up of the Diode.

The following pictures are of the control box I built so I can “Manually” control the pre-spool and turbo2 on functions. This will allow much quicker testing of different rpm/load/etc conditions initially. Once the best combination is found, the control box will be removed and the ecu will automatically run the sequential system. The control box will be plug and play into the body harness so I can install it at anytime if I want to play with it some more.

Everything was bought at Radio Shack for ~$20.

Still gotta slap some labels on there, in case I forget what does what, lol.

Here you can see the use of a potentiometer, resistor, and a transistor. Before my Automotive Electronics class, I didn’t know what any of them did. It’s cool because as I learn about this stuff in school, i figure out ways to implement the technology into my project! Special thanks to Mr. Schwid at Milwaukee Area Technical College, I am going to make you read this!

Final shot before screwing the box together. Everything has been tested and works beautifully!

My wiring diagrams. Just realized I forgot to draw in the 2 LED’s for the control box.

Been doing a bunch more research on Crome vs Neptune RTP and I for sure decided to go with Neptune again. I’ve been reading some things about Crome that I don’t like, plus if I sell my Ostrich and some other stuff I’ve been needing to get rid of, it really won’t cost me anything, and Neptune has so many awesome features!

very nice work, keep us updated! im really enjoying this thread ![]()

U R CRAZY!!! but wow i respect the work put in.

i’ll be checking this thread also to see the progress.

Those gauges seems really difficult to read, especially in that location and at that angle. I would push for switching faces.

Otherwise, illing to see results. :rockon:

yeah as far as mounting guages go, i like what you did with your boost guages, but if you wanna put some other guages in w/o putting them on your pillar or anything, i think you should load them like this

I think that would be baller.

But then again, those are my guages, so I’m biased…![]()

No, no… those are quite baller indeed! :werd:

yea, your gauges are sick for sure. Maybe I’ll pull the gauges off my pillar and do something like yours.

I cant knock you for trying… good luck, looks very interesting though.

:pop: :lurk:

hey im new to integras and that but my previous car was a jza70 supra with these ct12 turbos…

i had custom dump pipes made, bigger cooler. steel wheeled internals and a power fc

i was pretty sure this twin turbo setup doesnt work by 1 turbo kicking in after the other… and i think its a bit pointless unless one turbo was bigger then the other

toyota did release the ct20s (i think) from the jza80 supra which were larger and had the same problems… (these being the turbo exhaust wheels would spin off after running to much boost. hence why they were changed usually to a single but im a believer of more is better)

the 1g supra and soarer had a twin turbo setup with better turbos and can be boosted further then 14psi but the 1ggte motor is gay because its only a 2L and a a70 supra is heavy

i dont mean to put a damper on this for you i think its a good idea and would b very unique… the other thing is twin turbos will produce more heat aswell. it wouldnt hurt to have lagging on the exhaust side of things.

this is a huge job good luck with it

bump for an awsome setup.:hi5:

any new updates on it:sipread:

Slight deviation from the topic, G2White, are those 60mm or 52mm gauges? (2 or 2 1/4 in) I want to do something similar. Thanks.