Yo Man, got your pics just been busy. get back to you soon. Im really diging the new garage, im actually really of jelous of all that space LOL

Im looking forward to see progress on this harness. ![]()

Yo Man, got your pics just been busy. get back to you soon. Im really diging the new garage, im actually really of jelous of all that space LOL

Im looking forward to see progress on this harness. ![]()

The price of the tools is what really made me not want to go that route. I wouldn’t mind paying $100 for a quality plug but another $300 for a tool to use it? No thank you…

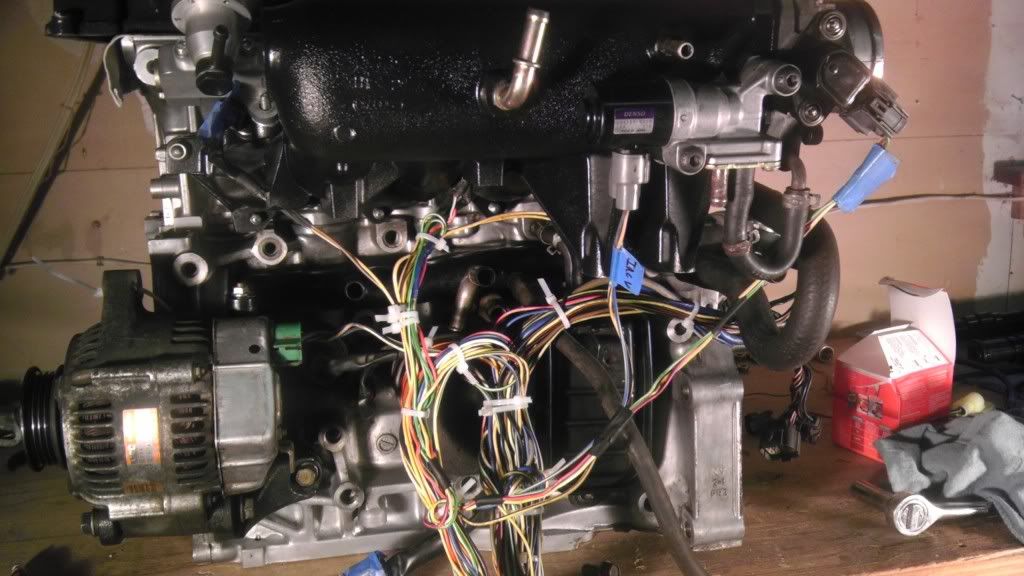

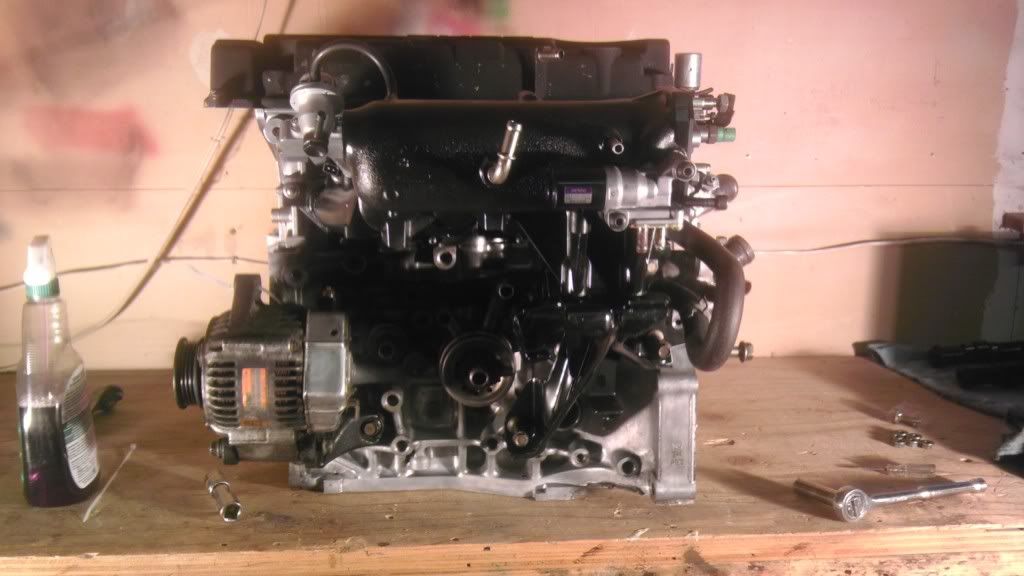

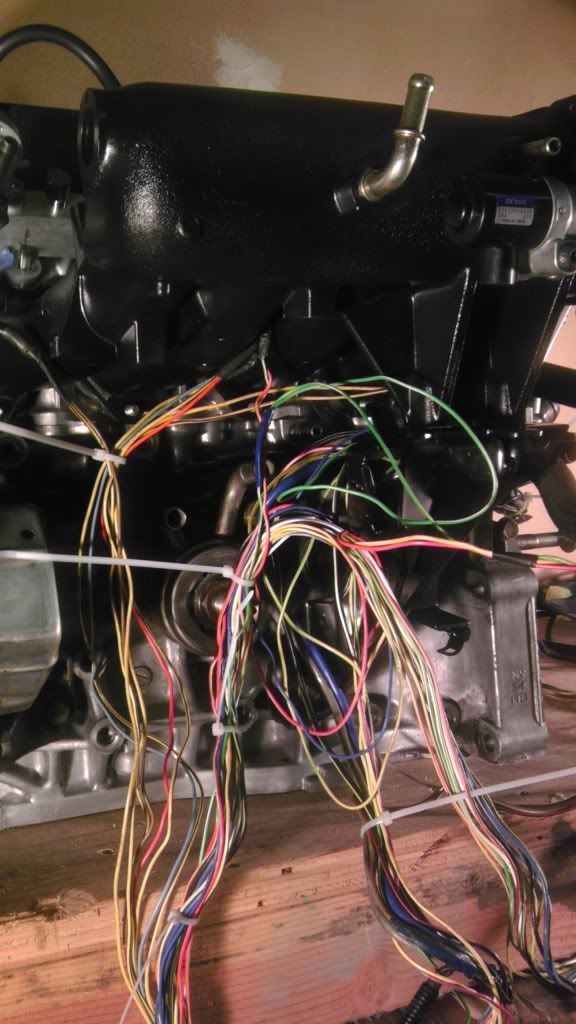

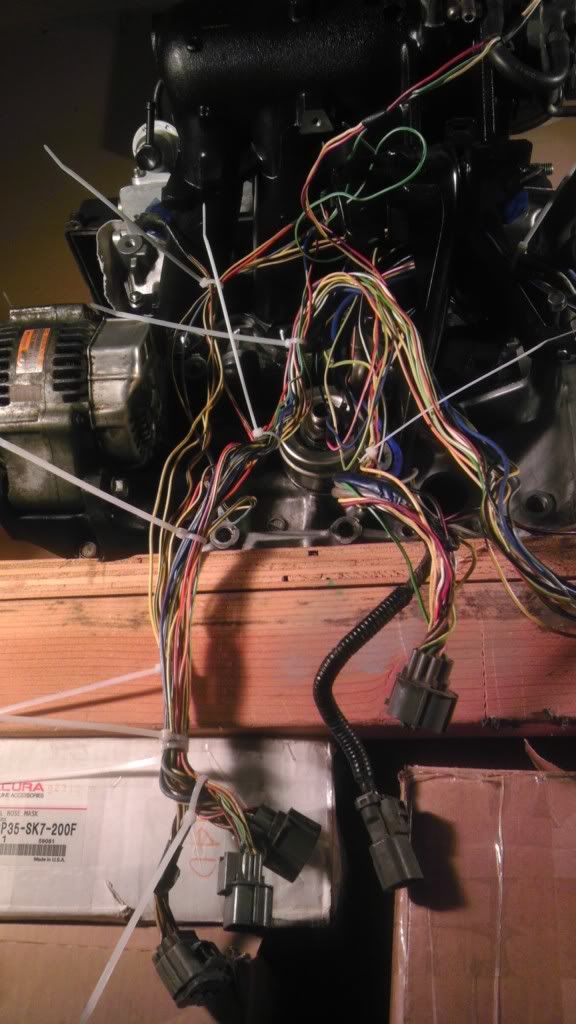

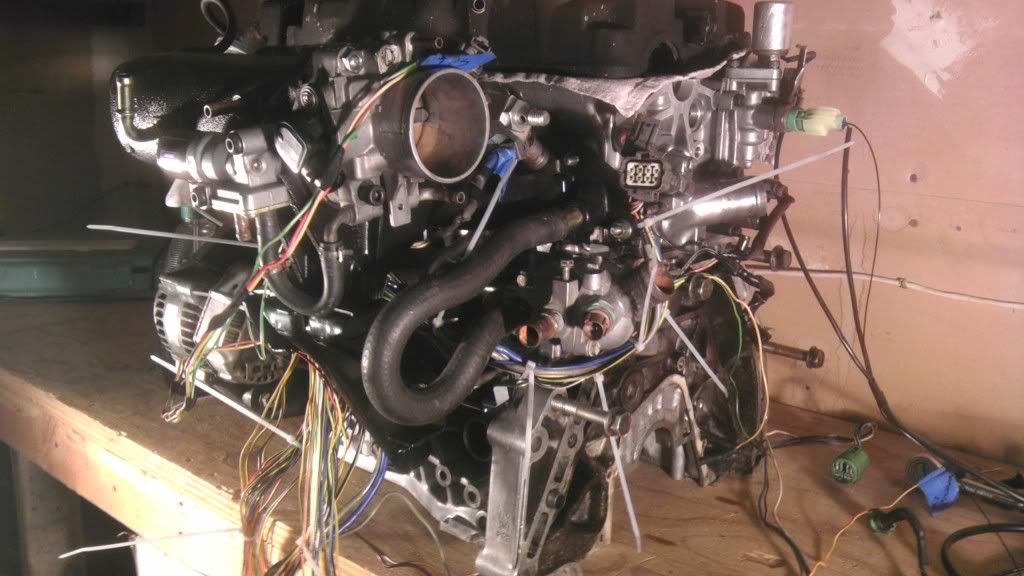

So as I stated earlier I’ve been working on my engine harness today. I got it mocked up on my old b18 block w/ b16 head and then changed my mind and assembled my b17 block/head just enough to sort it all out to length and rerun the wiring. Not quite finished yet but I ran out of time. I basically just have the sensors on the back of the block, alternator, and looming left. It still looks like a mess so don’t judge me, the finished product will be cleaned up I promise.

Bare harness, nothing separated out

B17 getting ready for mockup

Working on the passenger side plugs

Injectors/IAT

Backside of engine. Separating individual plugs out

Final picture of the day

I would have taken more pictures to illustrate what was happening but it was hard to show exactly what you were looking at. They all came out looking like a rats nest… It’s pretty straightforward though. As long as you know how the wires are run and keep it somewhat organized its not that intimidating.

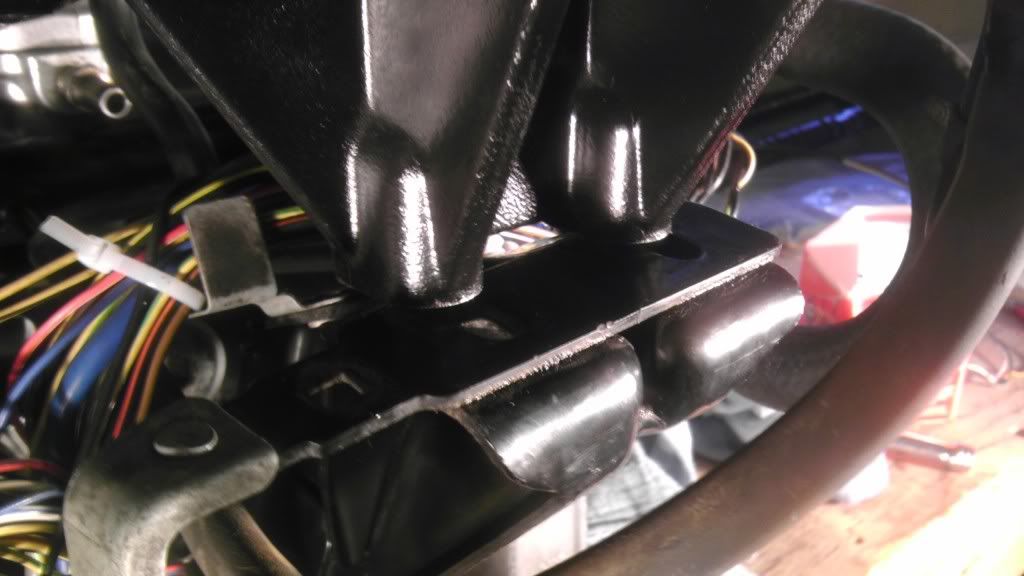

I do have a question though. Are the upper alternator brackets on a b18 different than B16/17? I was trying to use the bracket from the B18 for my mockup on the B17 and it was interfering with the intake manifold studs. I’m guessing due to the shorter deck height?

I was having a similar problem with my intake manifold brace (p73) which is why I believe it is due to the shorter deck height. I can’t imagine the lack of headgasket could possibly create that type of conflict.

[QUOTE=BLKACK1;2304194]Yo Man, got your pics just been busy. get back to you soon. Im really diging the new garage, im actually really of jelous of all that space LOL

Im looking forward to see progress on this harness. ![]() [/QUOTE]

[/QUOTE]

Thanks man! No sweat, I’ve been busy too. Not a rush at all. Hit me up when you’ve got time. Glad to hear you got your oil leak figured out and can finally enjoy your beast! ![]()

Ahhh Those pics bring back memories, or maybe they were nightmare. I guess it depended from night to night lol

to awsner your question, yes the 2 brackets or different but dosnt look like any thing a grinder wouldnt solve ![]()

That’s funny cuz I’ve read your tuck thread several times and throughout the day I kept thinking this looks just like blkack’s… Lol

Both the upper and lower alternator brackets are different? I thought maybe just the upper but I guess that makes sense. Damn

yes, pardon my re-tardness. LOL well im glad its helping out. hit me up with any question. all thought it looks like youve got a pretty solid handle on it…

I appreciate it! If I can just find time to work on it I feel like it should go pretty smooth. Between working 12 hour shifts, 1 1/2 hour commute and 3 kids, free time is hard to come by. Little by little though its getting there.

Your how to was very helpful man. Like I said I read it a few times and I felt pretty prepared before I even started it. You’re the man!

This aaaaaalmost makes me want to do a tucked harness… Almost, but not quite lol.

If I had a spare harness I’d think about giving it a go. Maybe down the road.

As BLKACK said yes the brackets are indeed different. Easy enough of a fix though.

Awesome progress though man! Keep us posted with with the final product.

Thanks man, maybe the final product will convince you…

So in order to make it work I’d just have to grind the top of the upper bracket off? I don’t see how/why you would modify the lower bracket. Meh, I may just source a B16/17 one. Not really looking to cut corners on this setup.

I’m currently out of town, but heading back home tomorrow… Give me a chance to look through my crap, maybe I can return the favor and find something that will work for you.

I’ll do some cross-referencing right now and see if the PN for the B17 unit is the same for any other b-series. Worth a shot!

Otherwise yeah, a simple notch with a grinder would suffice.

Awesome, thanks! If not don’t worry about it though. I’m a LONG way away from the time when I’m needing it so I’m sure I can find one before it would cause a delay for me. So I guess I need a B16/17 IM bracket then too huh? Glad I decided to mock it up on this engine after all!

The upper alternator bracket: 31113-P2T-000

'92-01 GSR

'99-00 Si

This makes me wonder though… I am almost certain that the bracket in your photo is the same one I am using on my LSV w/ITR manifold and I didn’t have a fitment issue at all. I think you’re right with the difference in deck height creating this issue.

Oddly enough, the 1993 GSR IM bracket (17132-PR3-010) is not the same as the B16…but it IS the same part# for the '92-93 LS.

The '90-91 LS pulls up as 17132-PR3-000…

All of the '90-93 IM brackets are listed as discontinued.

All of this is coming from AcuraOEMParts.com so don’t shoot the messenger!

Either way, I’ll check what I have and get back to ya!

Haha, I won’t shoot the messenger. That’s all great info for me! I already have a 92-93 ls IM bracket so I guess I just need to use that instead of the type r (p73) one.

Then all I need is an upper alternator bracket from a gsr or SI. Thank you sir! ![]()

Glad to see you givin so much love to my old motor ![]()

Looks good too!!

Thanks man! You wouldn’t happen to know what IM bracket you were using with the ITR IM would you? I’m still having clearance issues.

This is with the 92-93 LS IM bracket so I’m guessing my issue is being caused by the IM itself. Btw the other one I was using is a P30 not P73 like I said previously.

I worked on it a bit more this morning. Drivers side mocked up, just need to add VTEC and it’ll be finished.

Rear progress, still a mess but getting cleaned up. This is definitely the hardest area because you have so much extra wire and so many plugs all over the place. I still need to add the MAP sensor for the odb2 throttle body and figure out my routing after figuring out my IM bracket clearance issue and it will be ready to loom.

Hmmmmmm… I simply left my bracket off lol.

Not due to fitment issues, I simply deemed it unnecessary. Provided I stay conscious and never put much weight on the manifold, I’m not worried.

But I do understand wanting to keep it factory and utilize it.

That’s always an option. I just figured aside from it taking up a ton of space back here, it doesn’t do any harm.

Yea I don’t use the IM bracket either. If you have to pull the head with the motor in it makes it impossible.

Or the IM… When I installed my TB I needed to port-match.

Getting the manifold off would have been more of a pain than it already was lol

Yeah I think I’ve decided to just leave it off. Thanks guys.

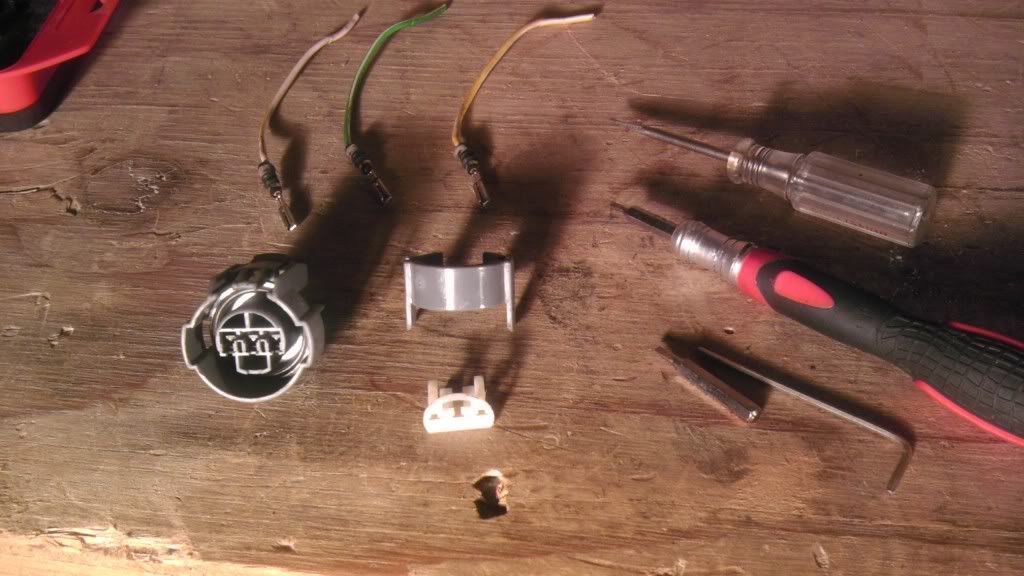

So I pretty much have the engine harness finished. All I have to do is add the MAP and VTEC wiring and loom it all up and it finished. I hate the cream color of the OEM MAP plug so I’ll be switching it out for a grey one. I got the plug depinned but then I realized the spare I cut from the junkyard was too short to use the wiring without it needing to be extended. So looks like I won’t be finishing it up til next week. I won’t be using any wiring unless it is the same color as it was originally to make troubleshooting easier later on.

Grey MAP plug all depinned

Pretty much where the harness is as of now