So I got my new clutch in a few weeks ago. Got a Clutch Masters FX350. I shouldn’t have any issues with this one slipping past 8lbs.

Then some friends and I pulled my trans last weekend. Btw, never doing it like this again. I would much rather just pull the whole motor

When I pulled the old clutch off I was surprised by the fact that it was still in great shape. There wasn’t a single hot spot on the flywheel or the pressure plate. They even still had the grooves in them fron when Exedy surfaced them in their factory. It did only have less than 10k miles on it, but for as much as I beat on it this little oe Exedy held up really well

Here is how the old stuff looked

Flywheel (Exedy 9.5lb)

Pressure plate (exedy oe style)

You can see the grooves still in it.

I put some new hondabond on the crank end plate thing and put in a new oem rear main seal

I didn’t even bother resurfacing the flywheel because it was in such great shape. I just put a new pilot bearing in it and threw it back on

Then I put the new Clutch Masters kit on

All of that went easy, then the issues started happening. Trying to get the trans back up and lined up was damn near impossible without scratching everything up and clunking it into everything. Never again will I do a trans this way. I will just pull the motor like I did the last time. Much easier that way. So once we struggled to get it up and on I ran into another issuel. The bolt on the top in the front ended up stipping the threads out of the block so it will no longer tighten…this caused the trans to have a small gap at the top in between the trans and the block =[ Oooor so I thought that was what caused the gap…

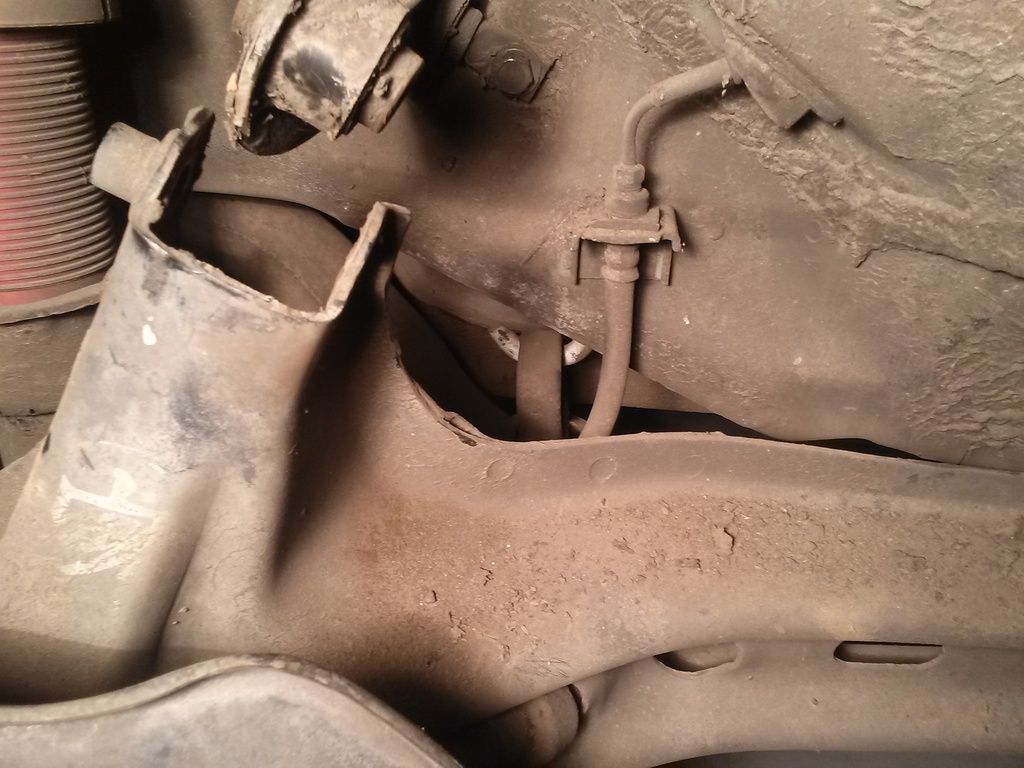

You can see the gap here, and the scratches on the trans =[

So after everything was back together I said ok there is nothing I can do about that gap right now so I’ll leave it and see if it effects anything. Well right when I put my key it I threw a cel for coolant temp sensor. I thought that was strange since I’ve never thrown that code before. I checked the connector on the head and it was in. I then traced the wires back and noticed that the wires for that temp sensor were caught in between the trans the block…FAIL! So that is the cause of the gap, not the threads being stripped for that bolt. I tried everything I could to get the wires out, but realized that without taking everything back off and wiggling the trans back there was no way to get those wires out. So I did what I had to do cause I was no about to rip my car all back apart less than an hour before the meet. I was determined to not have to drive my daily lol. I cut decided to cut the wires at both ends where it was pinched and make new wires to run to the coolant temp sensor. That solved the problem. Sucks I have that gap in there, but I drove the car and I’ve put 50 miles on the new clutch without issues from it. Car is acting normal and still drives perfect. I’ll have to fix that bolt that wont go in at some point, just don’t know how to go about it yet.

So as for how the clutch itself feels. They lied when they said it feels like stock lol. My leg is going to get BIG from using this thing. It might be the Hasport conversion kit that’s making it stiffer than normal, but idk it’s pretty rough. It also engages super close to the floor. It’s like an on off switch. I lift my foot less than half an inch and bam it’s fully engaged. I adjusted the cable in both directions to see if I could get it to engage higher, but with no luck. It’s either too loose and wont let me get into gear, or super tight and engages right at the floor. I’ve already stalled it out a few times cause I’m not used to it being so grabby. 'm hoping it will get better once it’s broken in, but I guess I’ll wait and see. As for how it grips…it grips like a beast. For me not getting on it or even pushing it yet it grabs way harder than the old exedy I was using. It’s an instant grab too, no hesitation or wait. It grabs and you know it immediately.

Anyway I’ll post back once it’s got it’s 500 mile break in done and let you know how it feels then. In the meantime I’ll leave this quick photo I took today while taking some photos for a friend