![]()

good looking car.

Thanks.

A few updates to add. Depowered the PS valve Body, replaced front wheel bearings & Tie Rods and added the extended studs (F&R) finally. I then went through the entire suspension system, loosened all bolts, preloaded the parts my jacking up each side and marking with torque seal. I also added the components for the Honda PWM to my ecu. When I bought the ecu, the seller said that it was PWM ready…well it wasn’t and this kept me from turning up the boost at the dyno. I didn’t even think to look, live and learn. I’m also working on relocating my Fuel Pressure Gauge. I’ll post more pics over the weekend.

wish you were around here…i’d love to get my wheel bearing done

Wow I stumbled upon this thread last night and just read through the entire thing. Damn fine build!

can you elaborate on “marking with torque seal”? What does this do, how is it done and why did you do it? I am about as backyard as it gets with “preloading” the suspension. When im done working on the suspension, i lower the car on the ground and lightly bounce up and down on each corner of the car before driving it (guessing not the best way of doing that)

In the industry I work in (aviation) torque seal is just a way of marking the fasteners to make it readily visible if they have loosened off.

forget what you know, your not even close. lol think of it like this. if you tourge all your bolts while the car is in the air. when the car is sat down, he bolts are tight on the suspension components and are trying to twist the bushings. this puts undue strain and premature failure. the proper way is to leave them loose. put the wheels on and set the car on something set of jacks, cinder blocks, wood. what ever your need so that the car sits under its own weight and you can still get to bolts, then tighten to the proper specs. I hope that makes sense…

Looking good Jdeck:up: How did those bearings treat you. mine didnt play nice at all. at least pressing them in went a lot smother ![]()

Yeah man too bad. For anyone in my area, I am more than happy to do your wheel bearings or any other work for that matter. I do work privately, anything from build you a motor, install a turbo kit, suspension etc.

Thank you. Appreciate the good words.

Correct, my uncle races F1 cars and put me onto using torque seal. It makes it really easy to visually inspect your car after some abuse.

[QUOTE=BLKACK1;2288069]forget what you know, your not even close. lol think of it like this. if you tourge all your bolts while the car is in the air. when the car is sat down, he bolts are tight on the suspension components and are trying to twist the bushings. this puts undue strain and premature failure. the proper way is to leave them loose. put the wheels on and set the car on something set of jacks, cinder blocks, wood. what ever your need so that the car sits under its own weight and you can still get to bolts, then tighten to the proper specs. I hope that makes sense…

Looking good Jdeck:up: How did those bearings treat you. mine didnt play nice at all. at least pressing them in went a lot smother :)[/QUOTE]

Exactly! Everything should be torque down tightly at the load of the car on the ground so that all rubber bushings are in a neutral position.

Thanks Glynn, I had to do a bit of wrestling ![]() to get these off but nothing out of the ordinary. I’m definitely glad there all done now.

to get these off but nothing out of the ordinary. I’m definitely glad there all done now.

I was able to remove and reroute the wiring harness that comes from the passenger side of the car last weekend to completely empty out both sides of the bay. Gonna work on the car this weekend. I’ll get some more updates and pics up.

Rolled the fenders this weekend. Pics of the 15mm Spacers, extended lugs, new tie rods.

Relocated the passenger side harness.

Working on hiding some more wiring, extended the dist wires so you won’t see the plugs.

good stuff.

Thanks

A little bit of grinding, 6an tap and the stock fuel rail looks a little more tolerable.

Polished up my intercooler before I put the bumper back on.

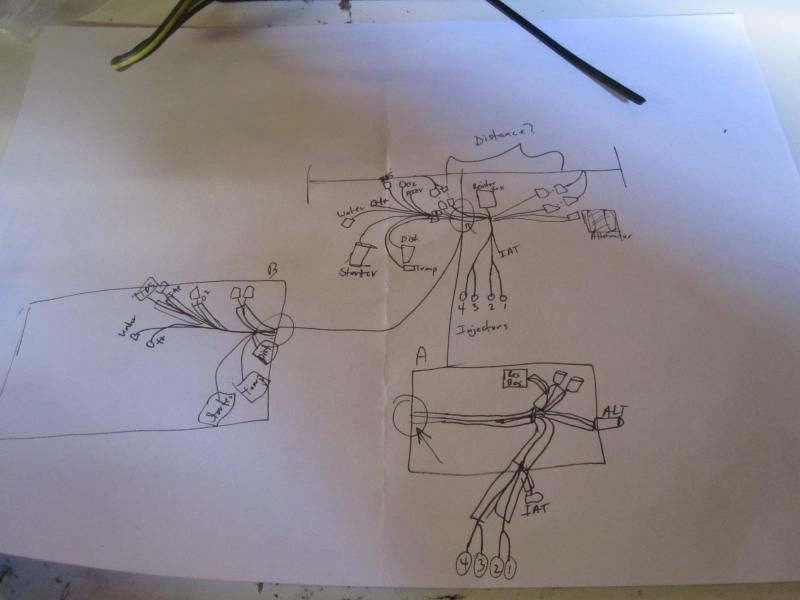

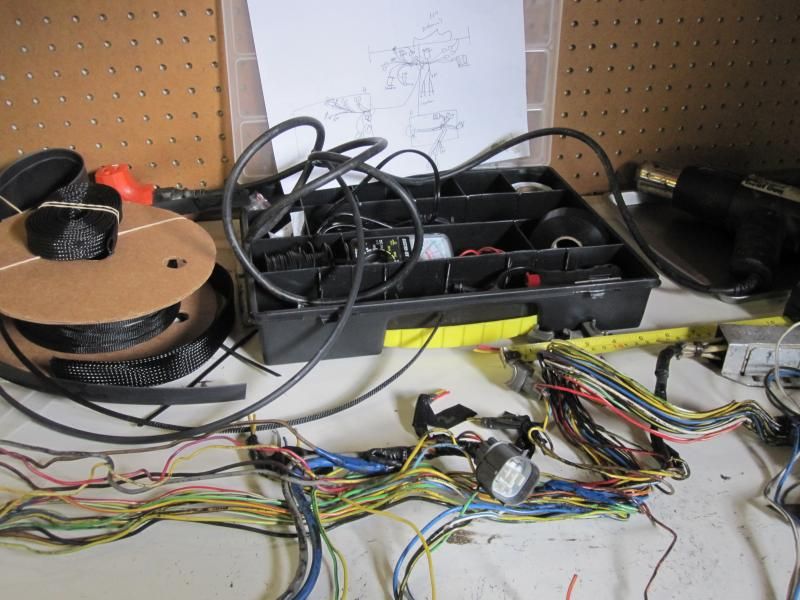

Started on my main wiring harness.

Car looks fantastic. Your wiring makes me have bad memories of the tedious nature of that work, i spent last winter doing mine. How do you feel about your turbo setup? has it been fairly maintenance free? Im debating putting an H22 in mine due to the great torque and reliability of a stock motor swap, but I have a weak spot for turbo’s.

Thanks TurboG2, appreciate it. I ordered all my sleeving and shrink, hoping to get started this weekend. I’ll post some pics up once I start. So far the turbo setup has been great! This is my second setup and I can’t say the same about the first. I was able to take everything I learned (and hated) from the first setup and improve on it.

When you do your wire tuck is your plan to bypass the shock tower plugs and wire in straight to the ecu? or are you going to pull the plugs back into the cabin and extend some of the wires to fit?

Are you talking about the passenger harness from the ecu? I pulled it back into the cabin and extended the wires to the location in the back of the block. I’ve got everything coming through an opening in the firewall.

Yes. Some guys are taking it a step further and depinning what goes from the ecu to the shock tower plugs and wiring the engine harness straight to the ecu connection so its cleaner

[QUOTE=BLKACK1;2288069]forget what you know, your not even close. lol think of it like this. if you tourge all your bolts while the car is in the air. when the car is sat down, he bolts are tight on the suspension components and are trying to twist the bushings. this puts undue strain and premature failure. the proper way is to leave them loose. put the wheels on and set the car on something set of jacks, cinder blocks, wood. what ever your need so that the car sits under its own weight and you can still get to bolts, then tighten to the proper specs. I hope that makes sense…

Looking good Jdeck:up: How did those bearings treat you. mine didnt play nice at all. at least pressing them in went a lot smother :)[/QUOTE]

thank you.

Got some good updates. I finished the harness and I was really happy with the result. I also made myself a continuity tester from and LED light, paper clips and two pens haha.